Thermoacoustic heat engine

Thermoacoustic engines (sometimes called "TA engines") are thermoacoustic devices which use high-amplitude sound waves to pump heat from one place to another, or conversely use a heat difference to induce high-amplitude sound waves. In general, thermoacoustic engines can be divided into standing wave and travelling wave devices. These two types of thermoacoustics devices can again be divided into two thermodynamic classes, a prime mover (or simply heat engine), and a heat pump. The prime mover creates work using heat, whereas a heat pump creates or moves heat using work. Compared to vapor refrigerators, thermoacoustic refrigerators have no ozone-depleting or toxic coolant and few or no moving parts therefore require no dynamic sealing or lubrication.[1]

Contents |

Operation

Overview of device

A thermoacoustic device basically consists of heat exchangers, a resonator, and a stack (on standing wave devices) or regenerator (on travelling wave devices). Depending on the type of engine a driver or loudspeaker might be used as well to generate sound waves.

Consider a tube closed at both ends. Interference can occur between two waves traveling in opposite directions at certain frequencies. The interference causes resonance creating a standing wave. Resonance only occurs at certain frequencies called resonance frequencies, and these are mainly determined by the length of the resonator.

The stack is a part consisting of small parallel channels. When the stack is placed at a certain location in the resonator, while having a standing wave in the resonator, a temperature difference can be measured across the stack. By placing heat exchangers at each side of the stack, heat can be moved. The opposite is possible as well, by creating a temperature difference across the stack, a sound wave can be induced. The first example is a simple heat pump, while the second is a prime mover.

Heat pumping

To be able to create or move heat, work must be done, and the acoustic power provides this work. When a stack is placed inside a resonator a pressure drop occurs. Interference between the incoming and reflected wave is now imperfect since there is a difference in amplitude causing the standing wave to travel little, giving the wave acoustic power.

In the acoustic wave, parcels of gas adiabatically compress and expand. Pressure and temperature change simultaneously; when pressure reaches a maximum or minimum, so does the temperature. Heat pumping along a stack in a standing wave device can now be described using the Brayton cycle.

Below is the counter-clockwise Brayton cycle consisting of four processes for a refrigerator when a parcel of gas is followed between two plates of a stack.

- Adiabatic compression of the gas. When a parcel of gas is displaced from its rightmost position to its leftmost position, the parcel is adiabatic compressed and thus the temperature increases. At the leftmost position the parcel now has a higher temperature than the warm plate.

- Isobaric heat transfer. The parcel's temperature is higher than that of the plate causing it to transfer heat to the plate at constant pressure losing temperature.

- Adiabatic expansion of the gas. The gas is displaced back from the leftmost position to the rightmost position and due to adiabatic expansion the gas is cooled to a temperature lower than that of the cold plate.

- Isobaric heat transfer. The parcel's temperature is now lower than that of the plate causing heat to be transferred from the cold plate to the gas at a constant pressure, increasing the parcel's temperature back to its original value.

Travelling wave devices can be described using the Stirling cycle.

Temperature gradient

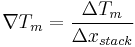

An engine and heat pump both typically use a stack and heat exchangers. The boundary between a prime mover and heat pump is given by the temperature gradient operator, which is the mean temperature gradient divided by the critical temperature gradient.

The mean temperature gradient is the temperature difference across the stack divided by the length of the stack.

The critical temperature gradient is a value depending on certain characteristics of the device like frequency, cross-sectional area and gas properties.

If the temperature gradient operator exceeds one, the mean temperature gradient is larger than the critical temperature gradient and the stack operates as a prime mover. If the temperature gradient operator is less than one, the mean temperature gradient is smaller than the critical gradient and the stack operates as a heat pump.

Theoretical efficiency

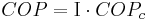

In thermodynamics the highest achievable efficiency is the Carnot efficiency. The efficiency of thermoacoustic engines can be compared to Carnot efficiency using the temperature gradient operator.

The efficiency of a thermoacoustic engine is given by

The coefficient of performance of a thermoacoustic heat pump is given by

Derivations

Using the Navier-Stokes equations for fluids, Rott was able to derive equations specific for thermoacoustics. Swift continued with these equations, deriving expressions for the acoustic power in thermoacoustic devices.

Efficiency in practice

The most efficient thermoacoustic devices built to date have an efficiency approaching 40% of the Carnot limit, or about 20% to 30% overall (depending on the heat engine temperatures).[2]

Higher hot-end temperatures may be possible with thermoacoustic devices because there are no moving parts, thus allowing the Carnot efficiency to be higher. This may partially offset their lower efficiency, compared to conventional heat engines, as a percentage of Carnot.

Research in thermoacoustics

Modern research and development of thermoacoustic systems is largely based upon the work of Rott (1980)[3] and later Steven Garrett, and Greg Swift (1988),[4] in which linear thermoacoustic models were developed to form a basic quantitative understanding, and numeric models for computation. Commercial interest has resulted in niche applications such as small to medium scale cryogenic applications.

History

The history of thermoacoustic hot air engines started about 1887, when Lord Rayleigh discussed the possibility of pumping heat with sound. Little further research occurred until Rott's work in 1969.[5]

A very simple thermoacoustic hot air engine is the Rijke tube that converts heat into acoustic energy.[6] This device however uses natural convection.

Current research

Orest Symko at University of Utah began a research project in 2005 called Thermal Acoustic Piezo Energy Conversion (TAPEC). [7]

Score Ltd. was awarded £2M in March 2007 to research a cooking stove that will also deliver electricity and cooling using the Thermo-acoustic effect for use in developing countries.[8][9]

Cool Sound Industries, Inc. is developing an air-conditioning system that uses thermoacoustic techology, with a focus on HVAC applications. The system is claimed to have high efficiency and low costs compared to competing refrigeration technologies, and uses no HFC, no HCFC, and no mechanical compressor.[10]

Q-Drive, Inc. is also engaged in developing thermoacoustic devices for refrigeration, with a focus on cryogenic applications.[11]

See also

- SASER, Sound Amplification by Stimulated Emission of Radiation

References

- ^ Ceperley, P. (1979). "A pistonless Stirling engine – the travelling wave heat engine". J. Acoust. Soc. Am. 66: 1508–1513. Bibcode 1979ASAJ...66.1508C. doi:10.1121/1.383505.

- ^ web archive backup: lanl.gov: More Efficient than Other No-Moving-Parts Heat Engines

- ^ Rott, N. (1980). "Thermoacoustics". Adv. Appl. Mech. 20 (135): 135. doi:10.1016/S0065-2156(08)70233-3.

- ^ Swift, G.W. (1988). "Thermoacoustic engines". J. Acoust. Soc. Am. 84: 1145–1180. Bibcode 1988ASAJ...84.1145S. doi:10.1121/1.396617.

- ^ Thermoacoustic Oscillations, Donald Fahey, Wave Motion & Optics, Spring 2006, Prof. Peter Timbie

- ^ P. L. Rijke (1859) Philosophical Magazine, 17, 419–422.

- ^ physorg.com: A sound way to turn heat into electricity (pdf) Quote: "...Symko says the devices won’t create noise pollution...Symko says the ring-shaped device is twice as efficient as cylindrical devices in converting heat into sound and electricity. That is because the pressure and speed of air in the ring-shaped device are always in sync, unlike in cylinder-shaped devices..."

- ^ May 27, 2007, Cooking with sound: new stove/generator/refrigerator combo aimed at developing nations

- ^ SCORE (Stove for Cooking, Refrigeration and Electricity), illustration

- ^ "The Technology". Cool Sound Industries, Inc.. Cool Sound Industries, Inc.. http://www.coolsound.us/technology.html. Retrieved 2011-05-31.

- ^ "Technology". QDrive. CFIC Inc.. http://www.qdrive.com/UI/StaticPage.aspx?sn=Technology. Retrieved 2011-05-31.

Further reading

- Gardner, D. & Swift, G. (2003). "A cascade thermoacoustic engine". J. Acoust. Soc. Am. 114 (4): 1905–1919. Bibcode 2003ASAJ..114.1905G. doi:10.1121/1.1612483. PMID 14587591.

- Frank Wighard "Double Acting Pulse Tube Electroacoustic System" US Patent 5,813,234

External links

- Score Stove, UK

- Los Alamos National Laboratory, New Mexico, USA

- Cool Sound Industries, Inc.

- Penn State University, USA

- The Power of Sound, American Scientist Online

- Thermoacoustics at the University of Adelaide, Australia, web archive backup: Discussion Forum

- Adelaide University

- Hear That? The Fridge Is Chilling, Wired Magazine article

|

|

||||||||||||||